After starting the socks business, a lot of questions will fill your mind. For instance, why does it take so much time to produce socks? How much does a pair of socks cost, and why are there various restrictions? This article will help you learn more about the socks production process, and provide better communication skills with the socks factory and gain more benefits.

Know the manufacturing process for socks OEM

Your first need to understand the manufacturing process of socks, which includes design, pattern making, yarn dyeing, prototype, manufacturing, setting, accessories (embroidery logo and grip for example), packaging, and delivery.

Sock design

Everything starts with an idea or a design. These ideas help the socks maker understand what the socks are going to actually look like. The customer will provide materials like design (structure and pattern), logo, color scheme, and anything that helps create a prototype.

Ideally, the customer would have a formal design file (Prefer ai or editable PDF. Jpeg, .png, .psd are also acceptable for design outsourcing.). This allows for the greatest accuracy toward the ideas.

This can also be done in many ways. The customer can either describe the ideas in words and the sock vendors work through the ideas together or even provide certain random socks styles similar to requested design/concept for further discussion. Or the customer has something concrete and sends a sketch. The best way is to find a benchmark brand or socks in the market that you like to use as a reference, and send photos, website links, or samples to the sock factory. In this way, the discussion can be more constructive and go through more details. The sock factory will advise how the socks to be made and what’s the suitable material composition. For example, standard dress casual socks for daily wear are mainly made from cotton, while polyester and nylon for athletic socks. Once you’ve decided on the design and socks style, you can move on to prototype!

Create prototype

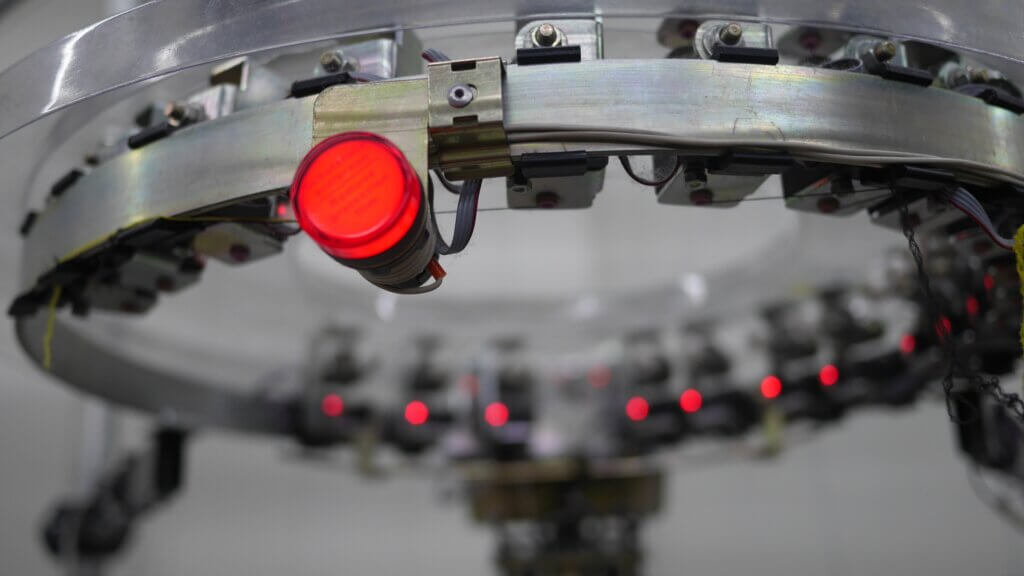

The sock factory uses the design and creates a pair of socks on the knitting machine. For Paultex, we will suggest customers what’s the best way (different needle count machines) to make unique spec socks and even outsource to the suitable partner for creating those uncommon. Once completing the socks sample, it will be sent to the customer for approval. Sometimes there’ll be a bit of back and forth adjusting the details. This is totally normal, and means the socks maker wants to provide the best result for your socks!

Once you’re satisfied with the prototype, the socks vendor starts mass production after order confirmation.

The making process in socks factory

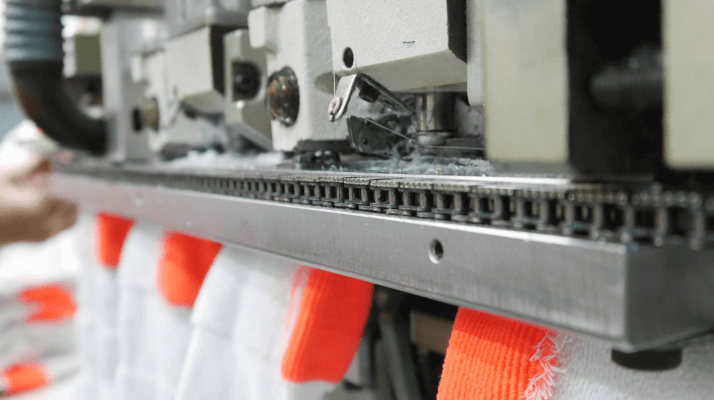

The socks vendor prepares the materials needed and begins mass production. Nowadays, socks are knitted by using an industrial sock knitting machine. This allows for the ultimate efficiency and productivity and keeps the cost as reasonable as possible. After the socks are knitted, it looks like a tube. The seams need to be sealed, which means the toes will be closed.

All that is left to do is to steam the socks to help create their shape (setting process). If you need embroidery or other accessories, additional processing is required after the above process. Please refer to this article for guide for custom needs.

Quality Control

In addition to confirming quality at the stage of prototype approval (checking pattern, color, size/length, stretching, packaging and so on), once the bulk production is complete, we inspect the socks for defects and ensure the products are made with the same quality and being trusted in the socks business. A Dollar Saved is More Than a Dollar Earned!

Order delivery

Finally, the socks will be shipped to the customer within the lead time the sock factory promised, which is also the final step of quality control. In the initial stage, we will give customers an approximate lead time. When the order is officially placed, we will give an estimated delivery interval. The exact shipping time along with commercial invoice and packing will be given 1-2 weeks before shipping.

If the customer expects specific shipping time, please kindly let us know before the prototyping. So we will be able to plan in advance and meet your needs.

Stay connected with the socks factory

Here the sock-making process is complete! Your idea has come into life and the custom socks are at your hands, ready to show.

A good sock factory will promptly send the photo of the sample socks to the customer and contact the customer in no time when there is any situation. It is important to maintain a smooth and instant communication channel so that you can quickly resolve the problem together. Please feel free and welcome to contact us @ Paultex. We are more than happy to discuss your customized requests of project with you to realize your ideas.