5 Steps to Making Custom Socks

Speaking about custom socks, the options are versatile. Here we break it down into different functions and see what suits you the most! If you want to know more about custom socks, you can check out the guide to making custom socks.

Step 1: Specify the Application

Function

Anti-odor & Antimicrobial Socks

A high-quality, breathable pair of socks is what you want. Materials that repel odors like coffee yarn (Recycled Polyester), Bamboo yarn, and wool are a plus. Lyocell, for example, has greater moisture absorption than cotton. Socks made of lyocell are durable, breathable, and also good for anti-bacteria. (Refer to here “WHAT IS THIS SUSTAINABLE YARN TREND ALL ABOUT?”)

Compression Socks

Compression socks can keep your legs from getting tired and sore. They ease swelling in the feet and ankles, which help prevent varicose veins. At the same time, the snug fit provides protection. For people standing all day at work or exercising for a long time, normal compression sock or sports sock with compression function are both recommended. Whether graduated compression socks or compression at specific areas, we can build up the structures to fulfill the customer’s needs.

Sustainable Socks

Sustainability is a future trend that people are growing aware of. If you’d like to know more about sustainable yarns, see here “WHAT IS THIS SUSTAINABLE YARN TREND ALL ABOUT?”. Choosing materials like rPET yarn, coffee yarn, lyocell, etc., offer functional features and cause less environmental degradation. Most importantly, this allows brands to develop a unique marketing strategy to bring value to end customers.

Winter Socks

Extra foot insulation from wearing socks can help to keep feet warm. A sock made of wool, acrylic and similar types of synthetic materials is preferred for cold weather. If the socks get wet from your sweat, they don’t lose the insulation properties.

Waterproof Socks

If you’re going on a hike, running through streams, river crossings, or stepping on the muddy ground, there’s a good chance you’ll need waterproof socks. Waterproof sports socks keep you away from cold wet feet while cycling, fishing, doing winter sports, or working in the rain. In addition, Waterproof socks can be used with shoes that accommodate thicker socks. It’s usually thicker than average to stay dry and warm.

Size

A good thing about custom socks is that they have a wide range in size! That makes a good reason to give custom socks as gifts. The picture shows different types in length. Choose the one that corresponds to the activity.

Step 2: Choose a Method to Make Pattern According to the Design of Custom Socks

When life is dull, colorful custom socks give that twist to ordinary life. The designs could be gradient colors, sophisticated patterns, curves, dots, and all sorts. Besides the traditional method of Jacquard, we offer different printing methods to better present complicated and diverse patterns. Here we introduce three main methods for selection.

3D Digital Printing

3D digital printing creates a seamless appearance and the colors stay permanent. Print socks are best used for items that require high amounts of detail and smaller quantity orders (flexible MOQ). Comparing to sublimation, this method allows the dye color to penetrate to the inner yarn. As a result, the patterns won’t be distorted or showing the white lines to distort the patterns when the socks are stretched. In addition, last-minute changes to the design before printing are also acceptable compared to the jacquard method.

Sublimation

Sublimation printing uses heat to transfer dye onto the sock. This method creates rich details that look identical to your original design. But the colors tend to fade under long-term exposure to sunlight. The color fade could also be caused by friction of movement, washes, and pilling of the fabric. Besides, this type of print socks seam on both sides, especially on thicker socks.

Jacquard

Jacquard socks are created by knitting patterns. The end product is breathable and comfortable, plus it’s cost-efficient. It could be applied to main materials like cotton, polyester, nylon, and other special yarns in specific parts to achieve the desired functional effect.

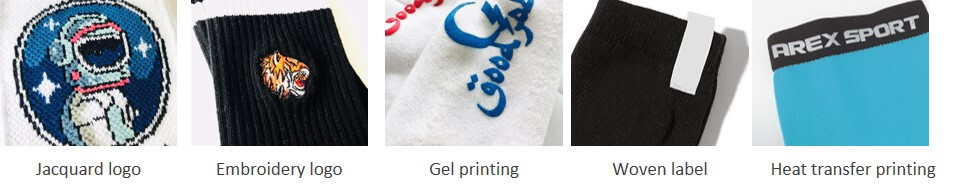

Step 3: Adding the Logo on Custom Socks to Highlight Your Brand

Usually, the logo of socks can be woven using the Jacquard method. But for more delicate patterns with small dimensions or different effects (to avoid pixelation for example), the below methods can be applied as well. The application could differ according to the logo size and where the logo is placed.

Embroidery Logo

The embroidery logo creates a dimensional texture and is long-lasting. It is great when you want the product to stay simple and neat, putting the focus on the logo. Using this method requires a certain amount of production quantity.

Gel Printing Logo (screen-printed)

Gel printing gives the sock a coating that will last for years. The colors are vibrant and durable.

Heat Transfer Logo (or Decal Transfer by Iron-on Stickers)

While the method is similar to gel printing, heat transfer allows more detailed and sophisticated images. It is more suitable for complicated design. However, the durability is not as good as gel printing unless stored and worn properly. When it comes to printing quality, there are a couple of ways to look at it: durability and resolution. While heat-pressed items yield a higher resolution image, the image won’t last as long as a screen-printed item.

Woven Label

Woven labels do not fade and are more resistant to being put through a wash. It gives the product a high-end feeling. But the minimum quantity is relatively high.

Step 4: Packaging option

The custom socks are almost finished, not until we give it a perfect ending – packaging. It determines the first image of the product, which makes it as important as the sock itself. Options like hangtag, sleeve, boxes, PE, and PVC bag are all available. Sustainable packaging is also an option. There is a growing demand from the market for sustainable packages to reduce environmental degradation.

Step 5: Shipping

The last step is to receive the custom socks! We ship by Air and Sea couriers for formal purchase orders. The samples will be sent to you by express deliveries like UPS/ FedEx/ DHL/ EMS. Welcome to use your own contracted shipping agency and please feel free to compare the fee with ours. Here you can also refer to more information from “How to find a good sock supplier”.

If you are looking for a custom socks supplier, please feel more than welcome to contact us @ Paultex. We offer a variety of options that could tailor to your special needs. There are a lot more methods for making custom socks. We are more than happy to discuss your sample or benchmark brand’s photos with you to realize your ideas.

If you are interested in the process of custom socks.please check Process.